Buildclass is an education product by Jimmi

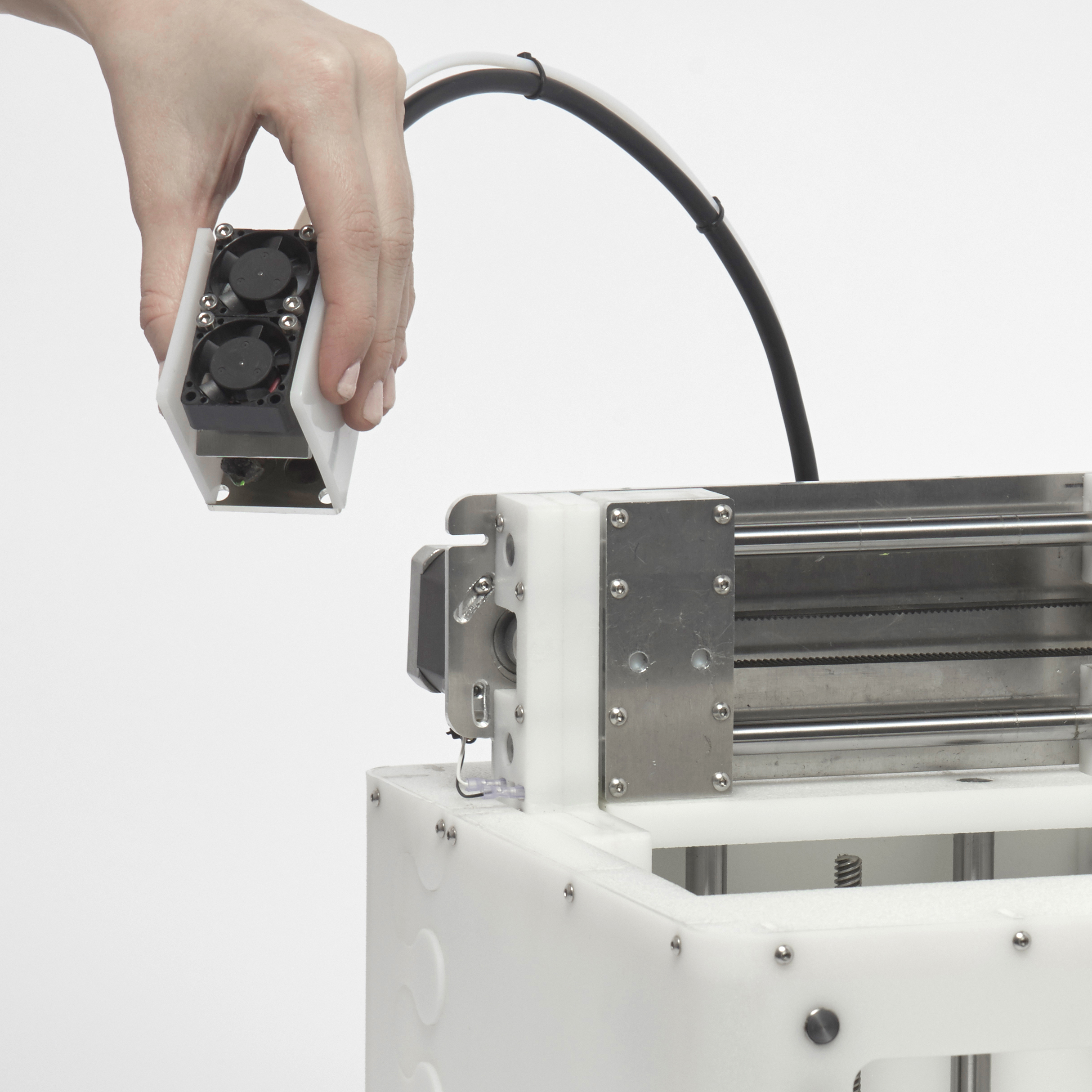

Buildclass is a two-day intensive workshop dedicated to advancing education in 3D printing. In these workshops, participants are guided through the building of their own 3D printer.

The Buildclass experience is an essential foundation for those who are new to 3D Printing, and a masterclass for those who are looking to take their knowledge to the next level. The workshop provides all necessary software, direction, and resources to begin 3D printing, to maintain the printer, modify, experiment, and become contributors to the open source community.

To learn more or sign up for a class, visit: www.buildclass.org

Our story

We were in our senior year at MICA studying sculpture and digital fabrication. Additive manufacturing had been around for 35 years, yet only recently was education in 3D printing becoming more widespread. We were introduced to 3D Printing in the Digital Fabrication lab (dFab) at MICA and became enamored by the possibilities of additive manufacturing but we realized that the only way to learn as much as we wanted about this technology was to design and build our own 3D printer. We made a printer for our own experimentation, printing with new materials and designing new processes and wanted to find a way to share this experience with others. Most affordable 3D printers at the time were either very limiting and only made for printing plastic, or they were DIY and had a high barrier to entry for a novice because of the oftentimes intimidating and unfocused nature of open-source information.

Jimmi launched Buildclass in 2015 as a education product, providing an accessible entry point to 3D printing with hardware that supported a culture of focused experimentation. We set out to build a community of advanced users of 3D printing and to integrate 3D printing into many people's practices.

A user-centered-design approach to hardware development.

Buildclass soon became the focal point for a user centered design approach to hardware development for Jimmi. We found that these educational workshops were the perfect environments to test and improve each iteration of our hardware.

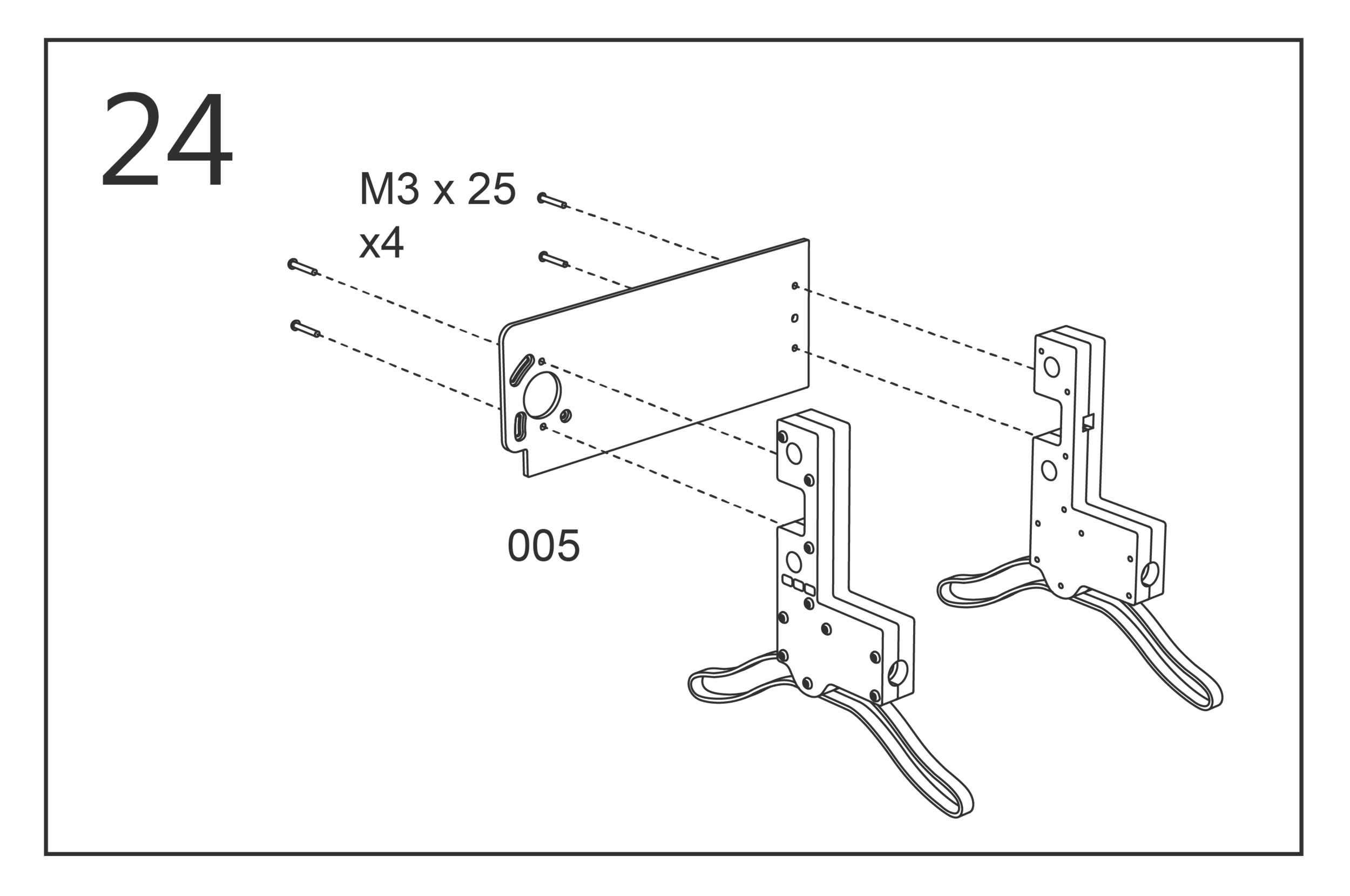

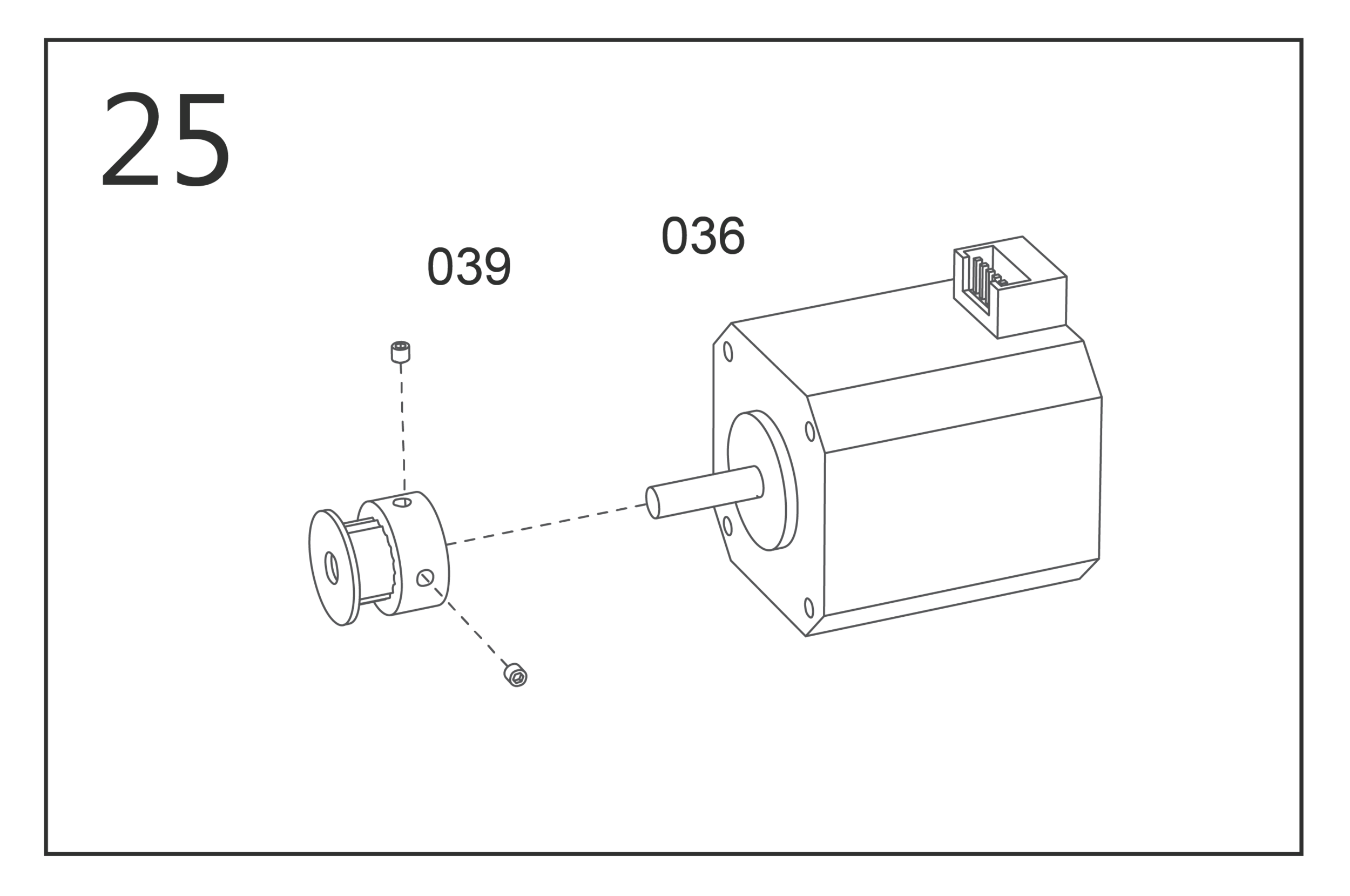

This user centered approach to hardware design enabled us to strategically create design solutions and resulted in a unique 3D printer designed specifically for the workshop experience. The design process is focused on refining features to make assembly, use and maintenance more intuitive and aesthetically rewarding for the end user.